It’s been a little crazy since my last post. I still had a few things I wanted to show off, I have my ever so beautiful router table (it’s definitely the work of an amateur…). I also made a nice cutting board for my girlfriend, so far it’s gotten good reviews. We’ll see if that holds, she’s only seen pictures!

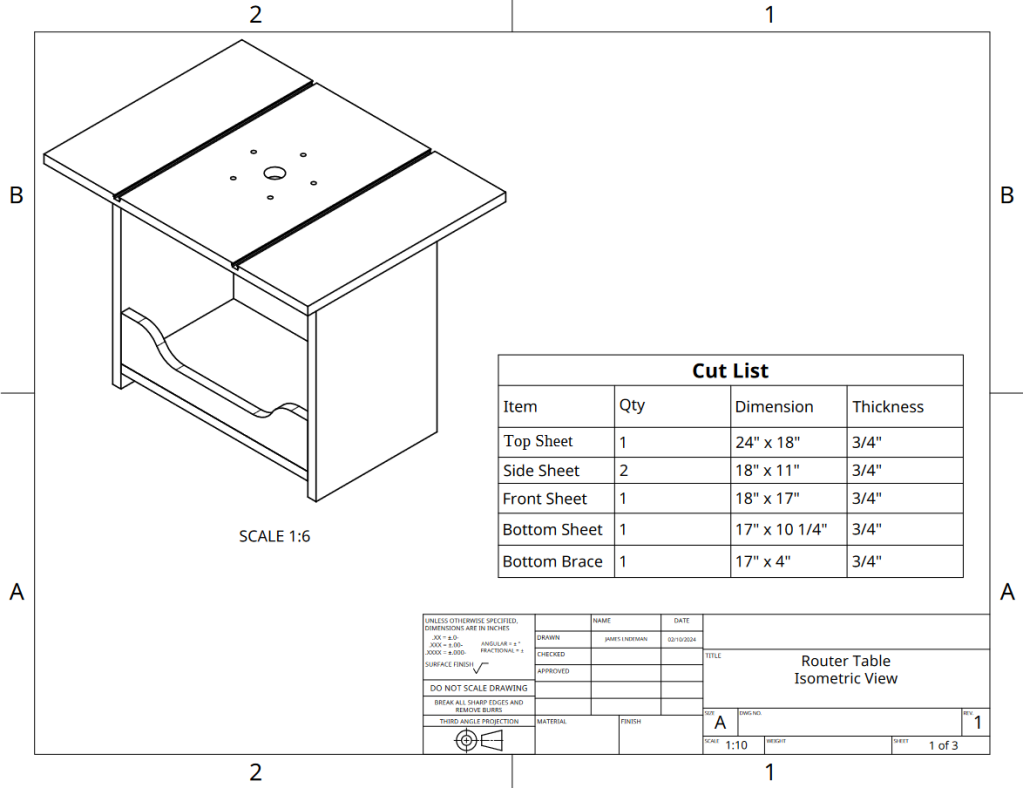

Router Table

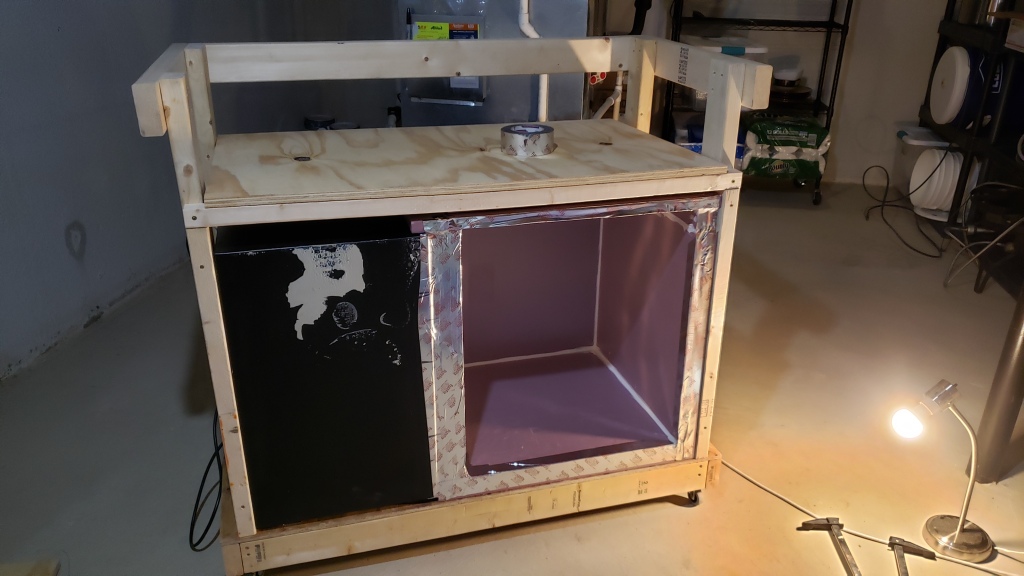

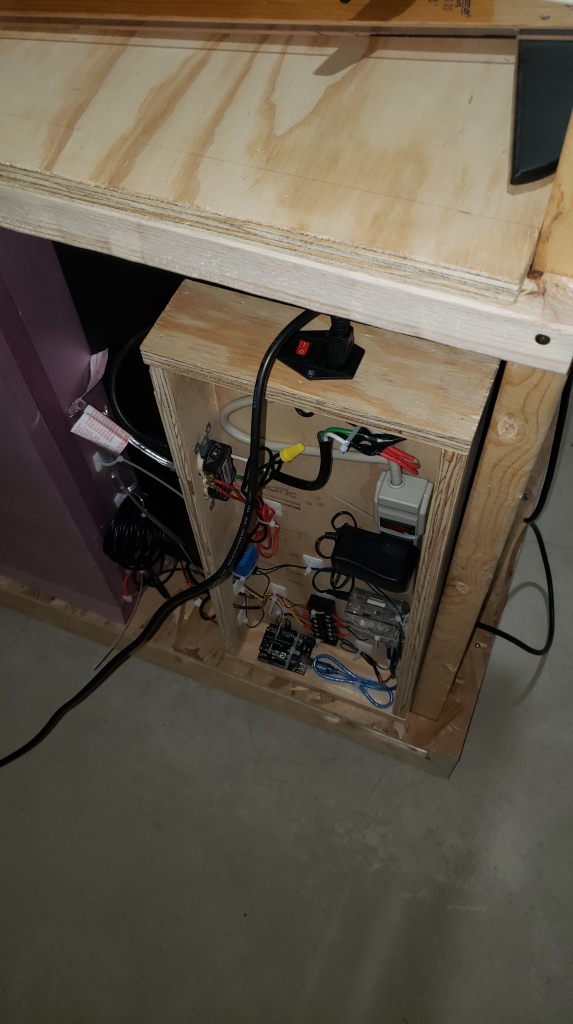

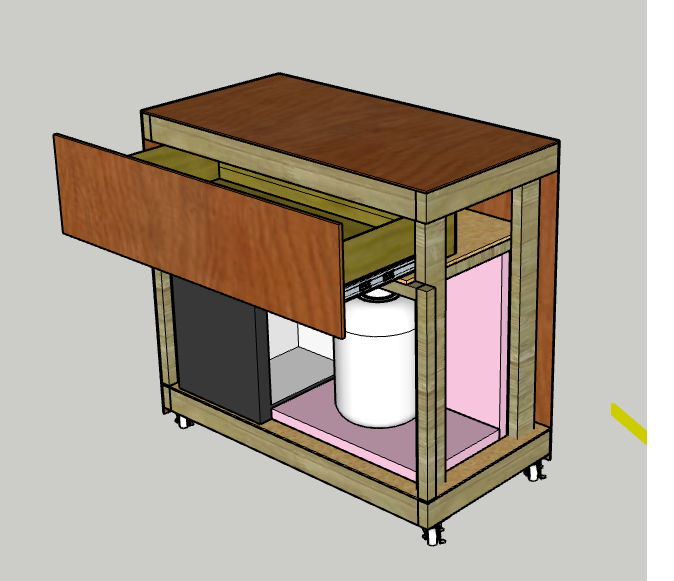

I eventually started getting tired of routing everything by hand, so I figured it was time to build a router table. This project was a little intimidating, because all the plans I was seeing on YouTube had cabinets and drawers, and fancy fences. I wanted something basic, I was surprised it was so difficult to find a basic one.

Eventually I found something basic, it was basically just drilling a hold through the top of the table, then putting mounting screws through holes in the top. They needed more than a countersink because the screws that hold the plastic router base are pan head and not flat, so a countersink wasn’t going to work great.

While this worked for the short term, it wasn’t going to be a long term solution. I wanted a better way to take the router out of the table if I needed to do freehand routing, because this way required unscrewing the router each time. I got a square piece of acrylic, removed the plastic plate it came with and mounted the square sheet to the base.

The Plan

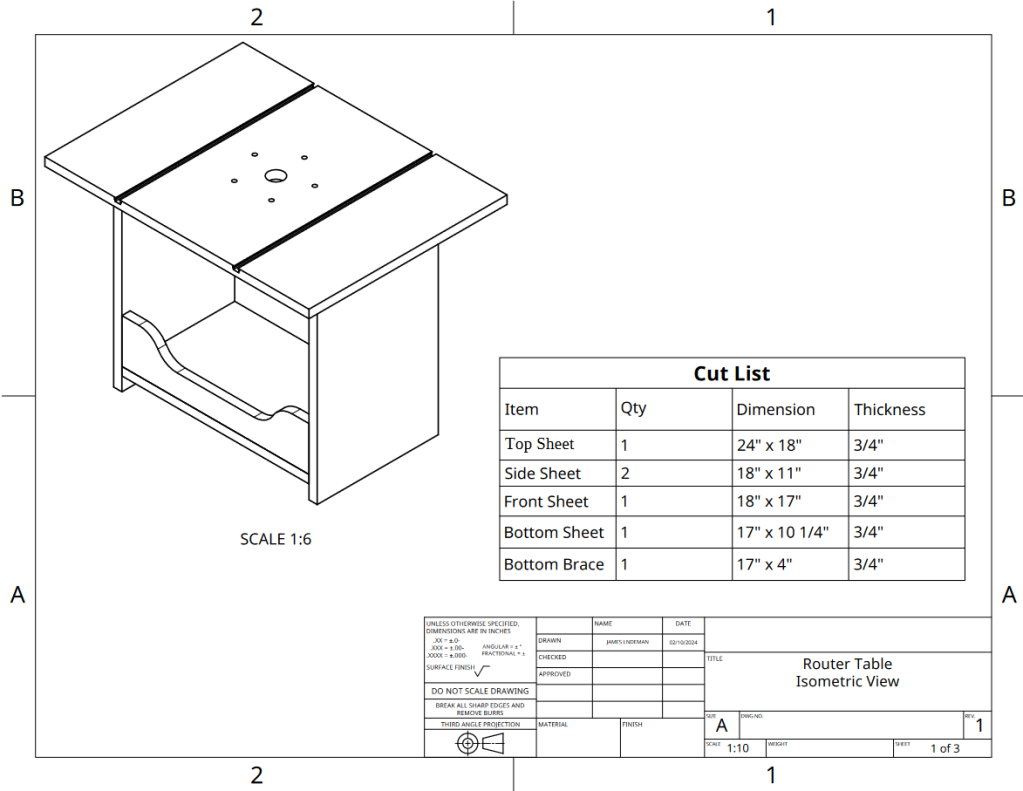

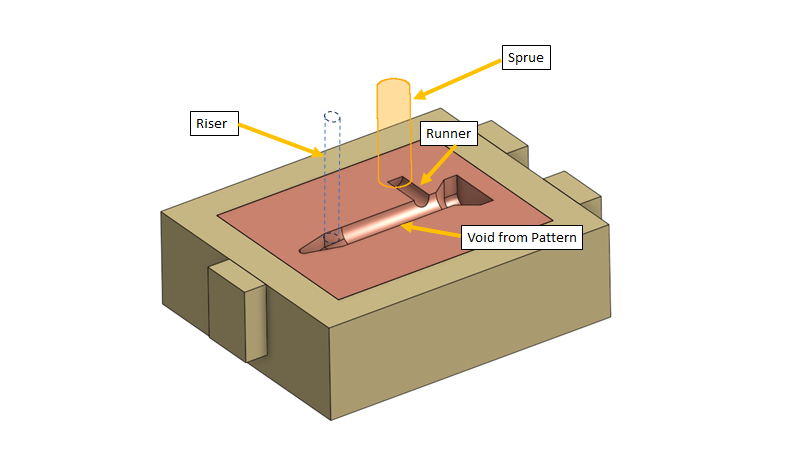

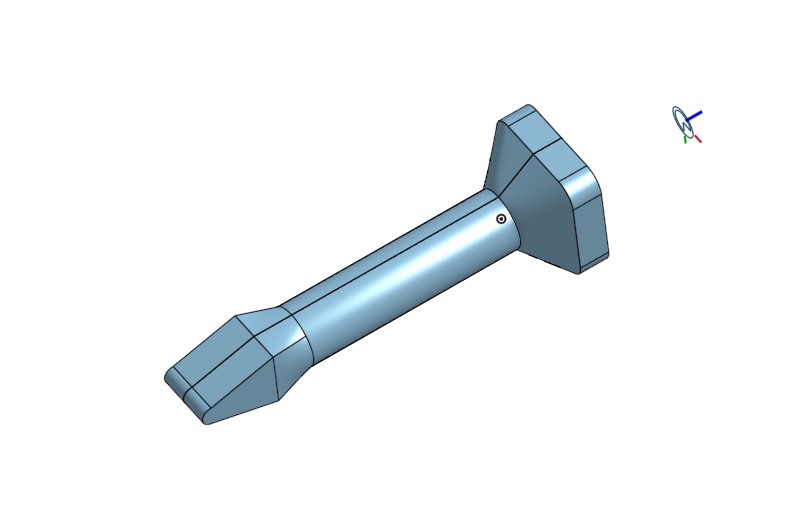

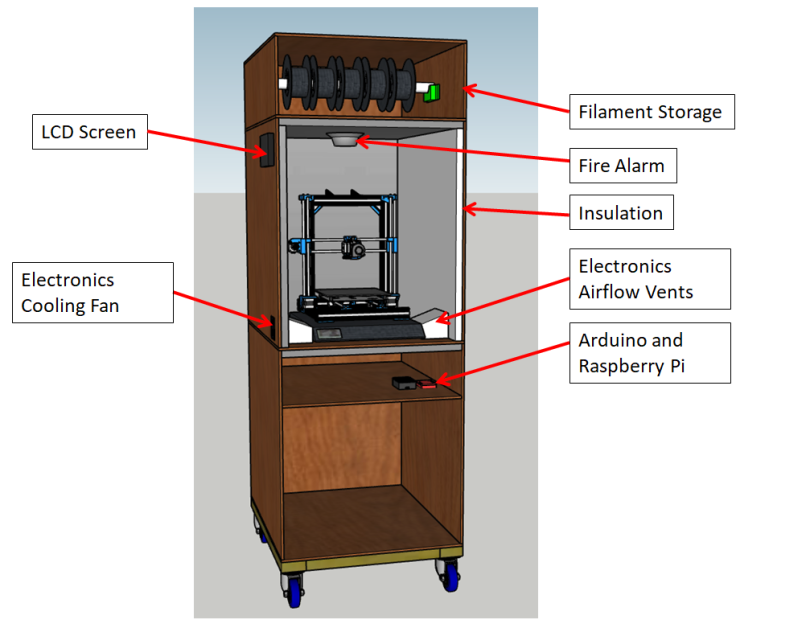

As I mentioned previously, I’ve started sketching everything out in OnShape. I like the drawings they put out and it gives me a good reference as I go through building something. I hadn’t modeled the acrylic as I hadn’t thought that far ahead with the design. Below was an initial cut list, it was a starting point.

I didn’t end up making the fancy curves on the bottom side support, I got lazy.

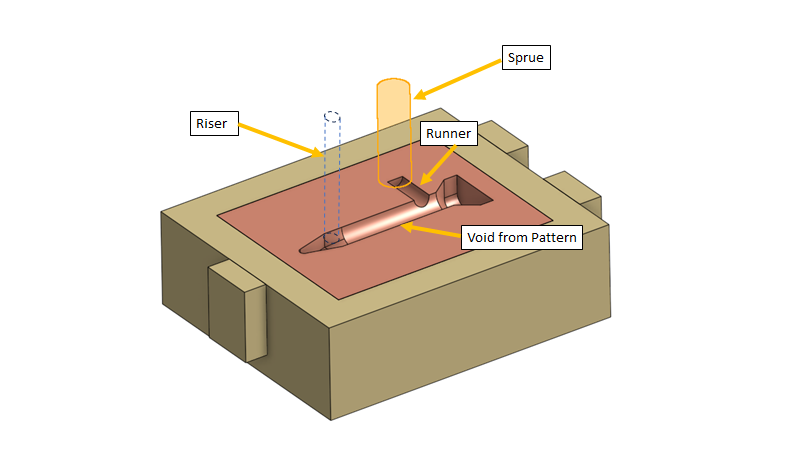

Cutting the Tabletop Hole and Landing

I decided to cut a hole out of the top surface, then cut a landing along the edge of the cut hole for the router to sit. I found a piece of acrylic that was just the right size, it was big enough that it allowed the full router to pull out of the top.

One thing I could’ve done differently is taken the hand holds off the side of the router, that would’ve meant the acrylic piece mounted onto the router could’ve been smaller. Always learning something…

In the above pictures, the left hand side photo marked out the hole location as well as the step where the landing was going to be routed. I cut the hole out with a jigsaw, which didn’t give the most square finish, but it worked.

I royally screwed up routing the landing. I didn’t think it through entirely and used the outside edge of the tabletop as a reference for the router edge guide versus a separate guide which was parallel to the inside hole edges, which was a really bad idea. I spent a lot of time trying to get it perfect, and it came out looking like crap. I also had some chipping on the edge closer to the side of the tabletop.

It looks like crap, but I finally got the acrylic sheet to fit in the landing.

It’s hard to tell, but I made the landing a little deep as I planning to add adjusting screws around the edge later to make the acrylic sheet flush with the tabletop.

I added a number of adjustment thumb screws with inserts and added additional with steps for bolts that would secure the acrylic to the tabletop.

One of the issues I ran into with routing the step lower than the edge of the surface was that after adjusting the thumbscrews to get the acrylic flush, the fasteners that hold the acrylic on would bend the acrylic downwards near the bolt. This basically eliminated the adjustments the thumbscrews were doing.

Below I sketched out a cross section of the acrylic to demonstrate what’s happening. As the bolt tightens down on the acrylic surface, it pulls it down, preventing it from being flush with the tabletop surface.

This was one of the issues with using the acrylic sheet, it flexed more than I thought it would. With the weight of the router base and the size of the hole, the acrylic sheet sags in a little bit. Something I plan to do in the future is add some gussets or ribs on the underside to stiffen the acrylic sheet. Other thing I might do is just get rid of it altogether and use a thinner sheet of plywood instead of acrylic.

I found that when I adjusted everything, the vibration from the router would cause the thumbscrews to loosen themselves out of the inserts. I have some loctite purple (low strength) I plan to use to keep the thumbscrews in place once they’re adjusted.

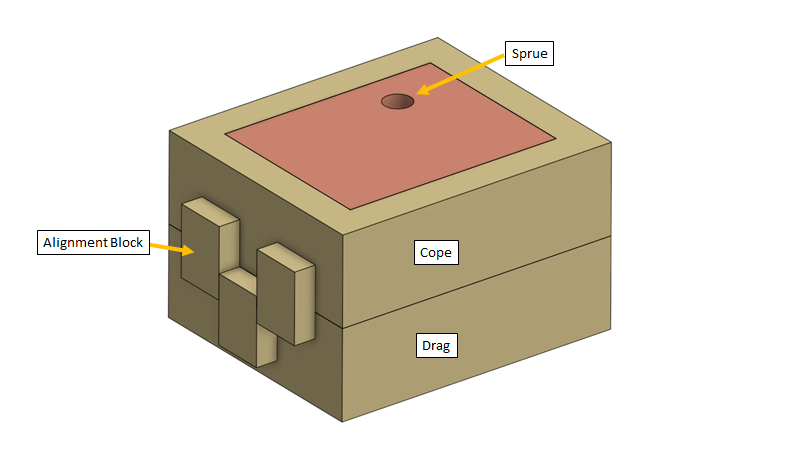

Adding some Rails and a Fence

While it worked fine once we got to this point, I wanted to add a fence. This would allow me to make straight slots, groves, or any kind of routing action that could use a fence support.

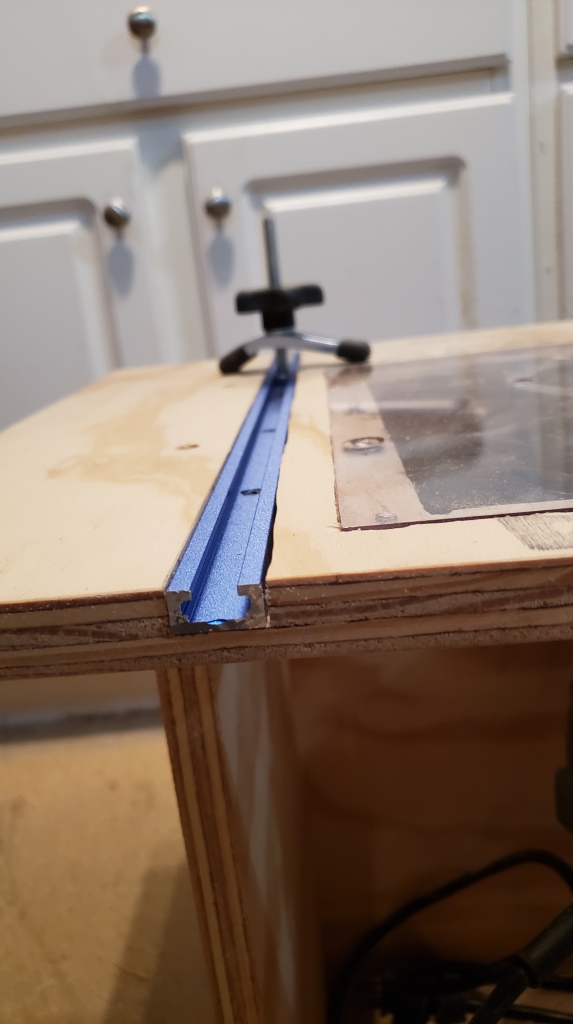

Learning from my mistakes with the landing, I clamped a piece of t-track to act as a reference edge for creating the t-track slots. This went a lot better than the landing.

With the T-track installed, all that was left is the fence. I glued up a few pieces of plywood into an “L” shape, cut some slots into the back for the t-track bolts to go through, planed the surface near the bit to make it flat, then drilled out a section for the router bit when the fence was in place.

The Final Result

While it didn’t look exactly like the plan I had started with, it works pretty well. It’s going to make my life a lot easier when it comes to routing.

Since I can’t leave anything alone, I do have some planned improvements.

- Add Loctite to the thumbscrews to prevent them from backing off

- Add support pieces underneath to stiffen the acrylic structure

- Modify the fence for dust collection, wood dust builds up quite quickly when using the fence

Lessons

I built this using existing plywood sheets, so if you need something basic and quick, it’s easy to make something work.

Cutting the Landing

As I mentioned earlier, I did a really poor job of this, partly because I didn’t have good references for cutting a straight line at a specific depth. Even though it works, it doesn’t look very nicely cut.

Landing Depth

I didn’t need to make the landing depth as deep as I did, as I discovered how much the acrylic would flex when bolted to the plywood tabletop. In the future, I’ll probably just cut it a little lower than flush, and adjust the thumbscrews as needed.

Using a Router

Whenever doing router cuts, it’s better to make small passes and adjust rather than try to take off too much all at once. Maybe once I get better at it I’ll be able to make deeper cuts once, but I ended up with too many issues cutting too deep when I try to cut too much from the slots.

Chip Out

Going forward, if I’m concerned about a surface chipping, I need to start putting tape over the area to try and control the chip out, it’s been happening lots lately, and it’s hard covering up chip out once it happens.

More Cutting Boards

I had some additional oak laying around, and now that I had my router table somewhat figured out, I thought it was time to make another cutting board. This one was quite a bit thinner than some of my other ones, I didn’t have a much usable skateboard deck strips to work with.

This time I decided to try and route channel along the edges, more as a drip guard for liquids. As expected, things didn’t go quite as planned. You can see in the picture below that I got burn marks in the channel, this is a mix of things when cutting the channel out. Next time I’ll have to move a little quicker and adjust the router speed to prevent the bit from burning the wood. Otherwise, I really like how the oak contrasts with the maple when you add the cutting board oil.

When you compare this against one of my earlier cutting boards, you can see how much smaller it is. This is nice as it’s not nearly as heavy as the maple cutting board I made.

What’s Next?

Aside from woodworking, I recently went to New York for the first time, oh my what a city that is. I’ll probably plan on doing a little writing on that city. Times Square was a little overwhelming to say the least.

I do have a lot more projects planned, it seems like there’s never enough time to work on everything. I have yet to figure out where my priorities are when it comes to my hobbies, I’m stuck between woodworking, electronics, golf, skateboarding…I’ve stretched myself a little thin!

More to come soon. Thanks for reading!